How does it work?

Option 1.

Production only.

Production time:

Between 10- 15 days

Good when:

You have your logos or graphics files sorted, you know exactly what you want to create, and you are ready for printing or embroidery.

Good for:

Promotional products

Re-runs

Tight deadlines:

We do have the ability for turnaround within 2-5 working days if urgently required.

-

Finalised logo or design files.

Print ready, high-resolution vector files, with CMYK colour references.

Type of products selected and specified (for example hoodies, hats, tees, etc)

Quantities confirmed.

Budget confirmed.

Option 2.

Design & Production.

Production time:

Between 14 - 90 days

Good when:

You need a little help on the design side or making production decisions. Could be fine tuning your logo, illustrations, or graphic designs, or advice on colours, sizes or quantities. Also considerations around additions such as neck tags or swing tags.

Good for:

Promo Gear

Work Gear

Retail Gear

-

You have a vision, but may need help with the steps to get there.

You have a budget in mind to work with.

Option 3.

Product Development

Production time:

Between 28 - 180 days

Good when:

You are looking to create a completely new or unique clothing product, and want help with the entire process. You might also want assistance with logo design, branding and marketing to create a unified product experience throughout.

Good for:

Work Gear

Retail Gear

-

You have an idea of what you want, but may need help with completion.

You might have begun the design process and have concepts.

You have an idea of what garments you want to produce.

You have a budget in mind to work with.

3 is the magic number…

We keep it simple, connecting New Zealand’s world leading blank clothing company AS colour with the country’s most reliable and friendliest printers Platform Print. Guided by the reliable steady hand of Oaia Clothing Company. A simple & solid connection.

Printing options & processes.

There are many different printing options for a range of scenarios and products. It's worth mentioning that fabrics and quantities can also determine the ideal printing application. Here are some of the more common options and applications.

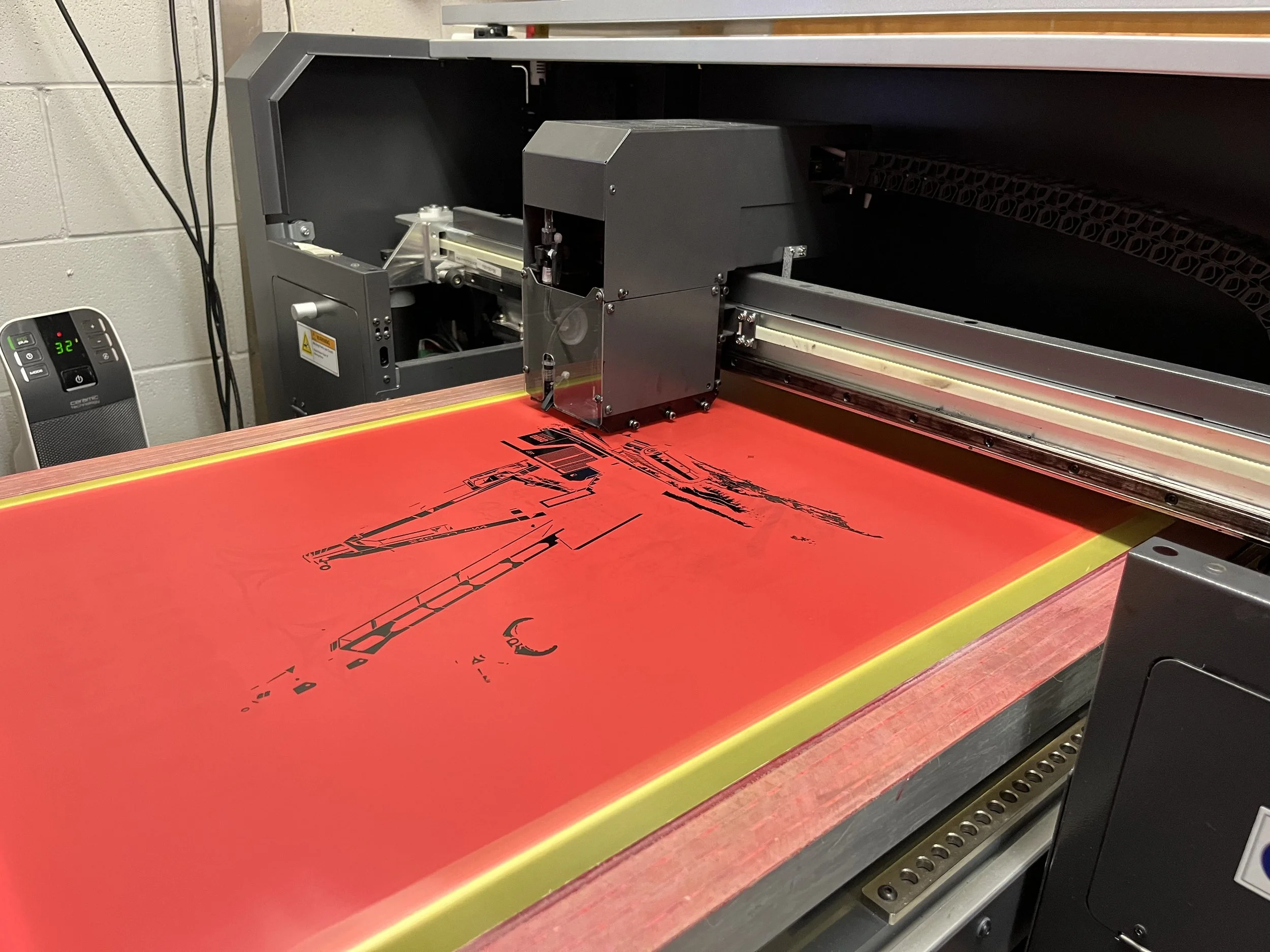

Digital printing.

This evolving technology has been a revolution within the clothing industry over recent years. The upsides are many: it's versatile and cost-effective, and also offers sustainable ways to produce intricate and high-quality designs on fabrics. There are several types of digital printing techniques used, each with its unique advantages and ideal use cases. Here are the common options we offer.

DTF (Direct to Film).

The most commonly used Digital Printing technique is in fact DTF. The process essentially prints a design onto a film, then the film is heat pressed onto the garment or product. This method offers high resolution prints with intricate details and delivers vibrant & precise designs on garments. Ideal on a range of cotton and nylon products.

Simulated Printing.

In short this is screen printing without the screen printing. It's the process of digitally printing a design onto fabric that mimics the appearance of traditional screen printing. This technique allows for high-quality, detailed designs with a soft hand feel and is often used for custom or limited-edition apparel.

Dye-Sublimation Printing

This is a process whereby heat is used to transfer dye to fabric, typically polyester. The design is printed onto a special paper (with sublimation ink), then heat and pressure are applied to transfer the design onto the fabric, where the ink turns into a gas and bonds with the fibres.

Produces vibrant colors

Ideal for all-over printing

Durable: won’t crack, peel, or fade

Soft finish (ink bonds with the fabric rather than sitting on top)

Best for: Polyester fabrics, sportswear, athleisure, activewear, and custom garments requiring full-surface printing

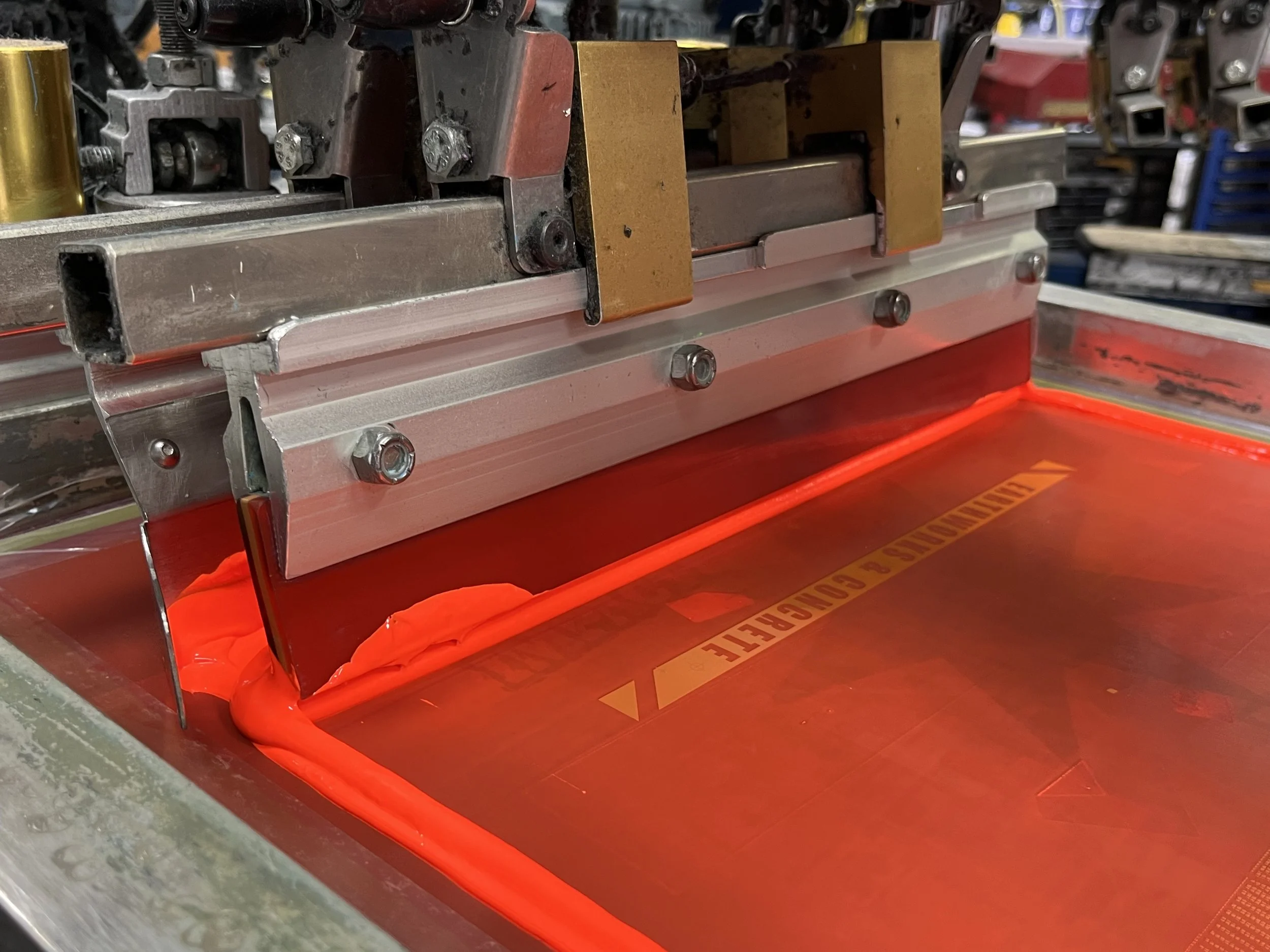

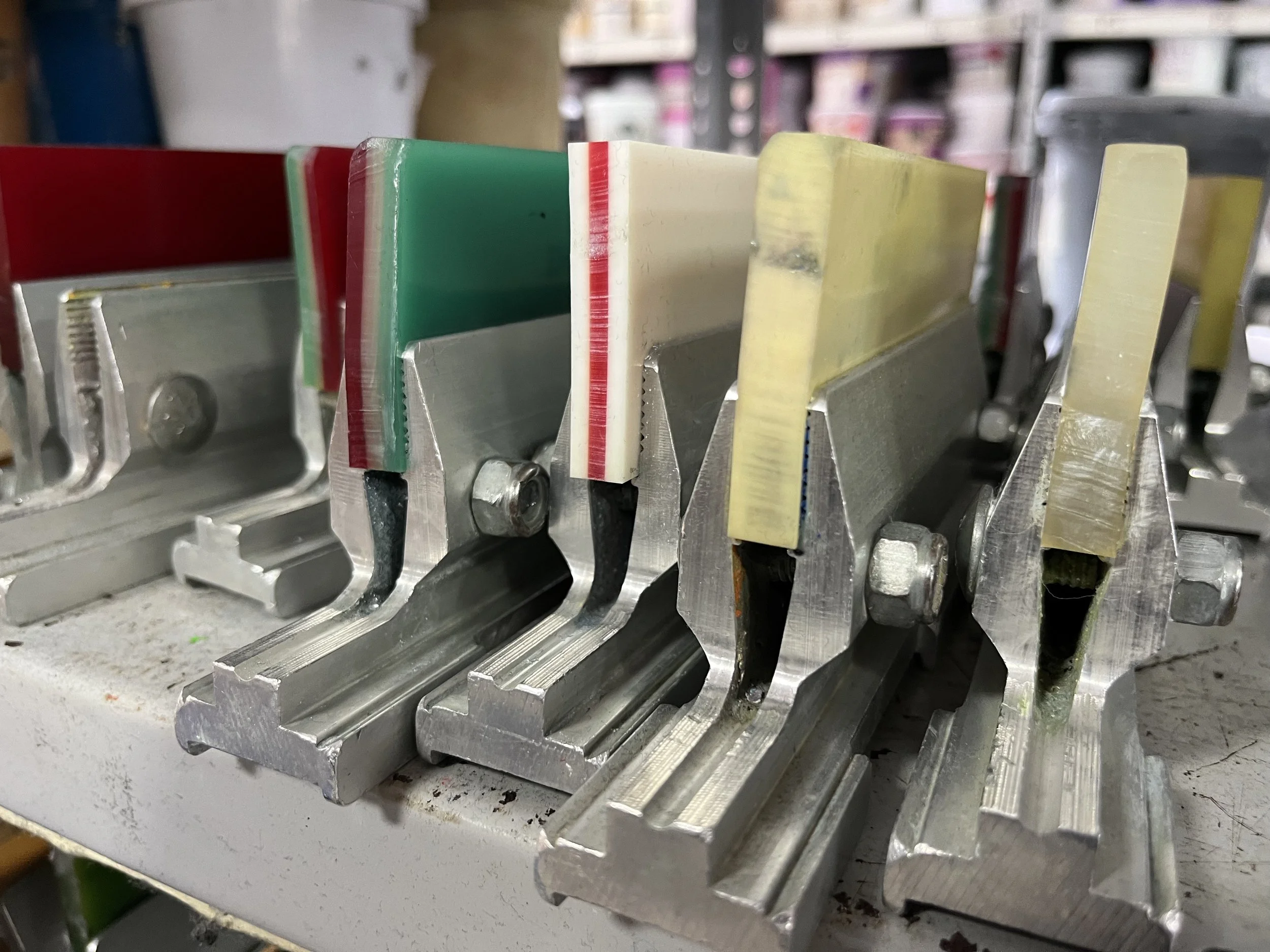

Screen Printing

This is the traditional method, and a much loved method – because it always delivers a standout result. It's also one of our most common methods. Screen printing is the process of applying separate layers of ink through mesh screens onto fabric, giving a long-lasting, high-quality vibrant print. Suitable for most garments, hats & caps.

20 units or more required.

Embroidery

All types of embroidery are available. Can be applied direct to garments like tees, sweatshirts & polos shirts. Also includes badges for caps, hats & beanies, or direct sewing to most of the accessories within the AS Colour range.

Neck labels

Customised neck labels can be either sewn to garments or printed directly onto the inside of the garment. Quantity and turnaround time is a key a consideration in terms of how viable this option might be for you.

Swing tags

Customised retail swing tags can be added to your garments during production. This means your product arrives retail-ready; For example information such as barcodes, pricing, and sizing added to a swing tag and completed and delivered at the same time as the clothing.